Copyright © 2025 K.G.Matzen. Powered by iglobalwin.com

Usage Conditions, Advantages, and Disadvantages of Various Types of Sedimentation Tanks

2025-06-24

Sedimentation tanks (including primary and secondary clarifiers) are the core solid-liquid separation units in wastewater treatment processes. Their performance directly affects water purification efficiency, the stability of subsequent processes, and operational costs. The characteristics of different sedimentation tank types are explained below in terms of “Applicable Conditions,” “Advantages,” and “Disadvantages.”

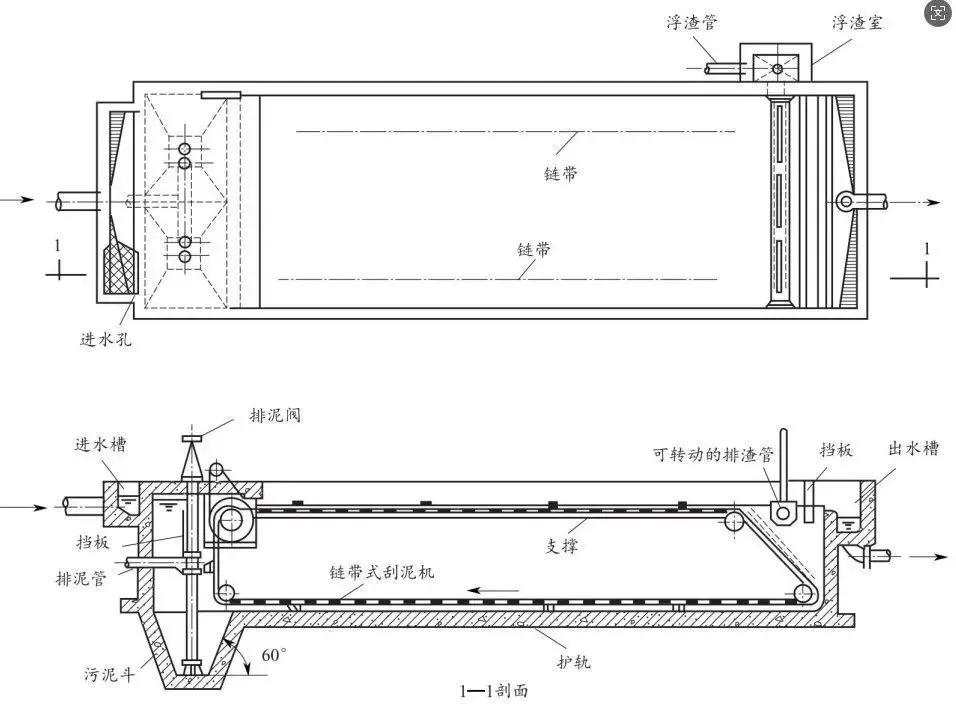

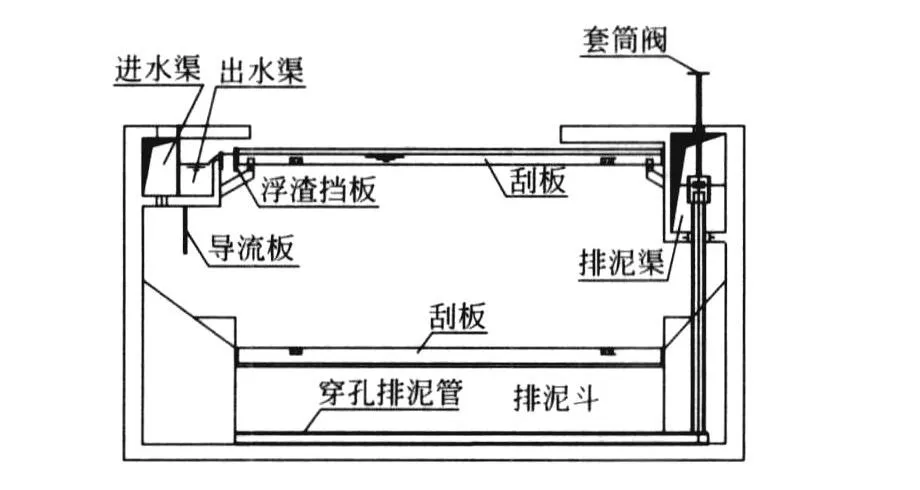

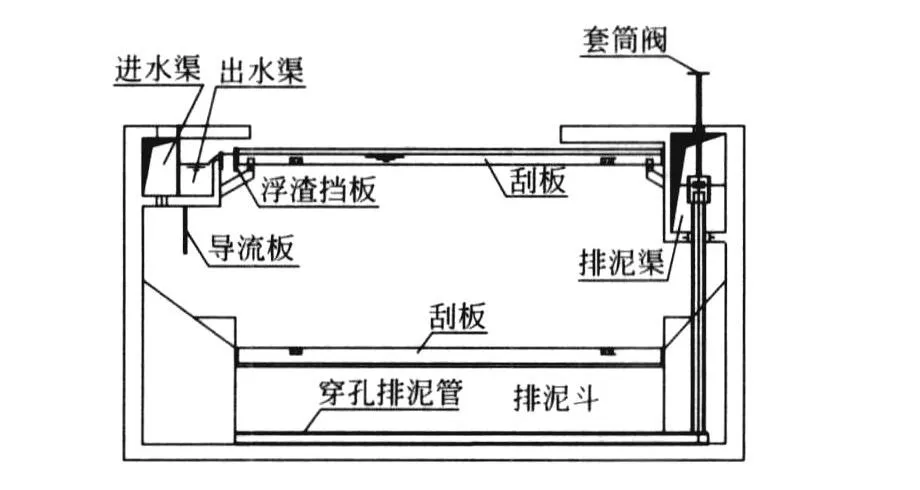

1. Horizontal Flow Sedimentation Tank

Applicable Conditions:

• Generally used in medium to large-scale water treatment plants

• Can be used as a pre-sedimentation tank when raw water has a high sand content

Advantages:

• Strong adaptability to water treatment and stable performance

• Easy operation and management

• Low construction cost and relatively simple to build

• Effective sludge removal when equipped with mechanical sludge collectors

Disadvantages:

• Requires large land area

• Poor resistance to shock loading

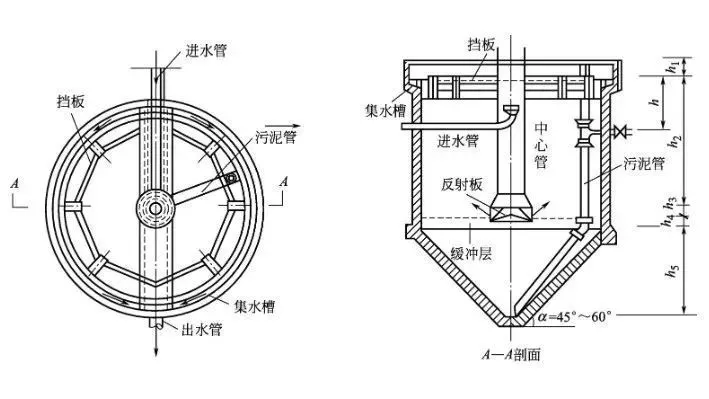

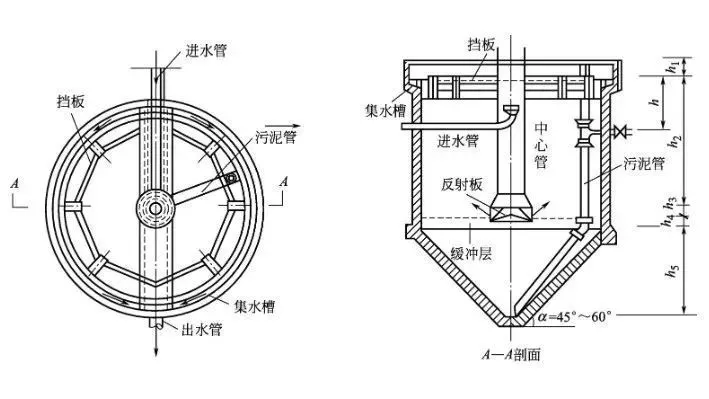

2. Vertical Flow Sedimentation Tank

Applicable Conditions:

• Generally used in small-scale water treatment plants

Advantages:

• Small land footprint

• Compact structure facilitates sludge removal

Disadvantages:

• Difficult to construct

• Low upward flow velocity leads to limited capacity and poor sedimentation efficiency

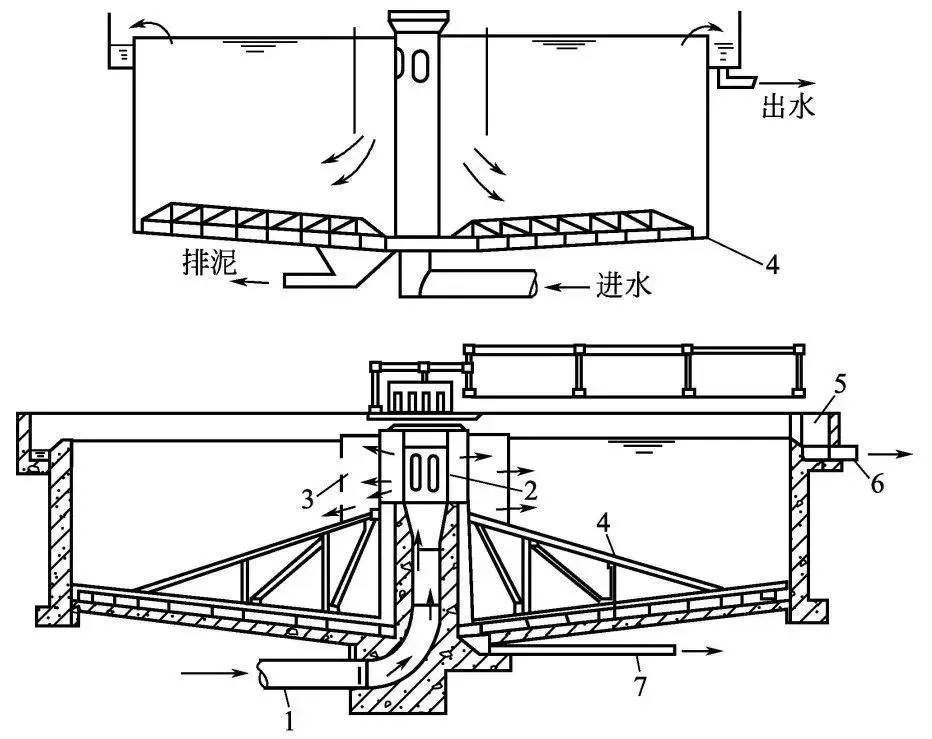

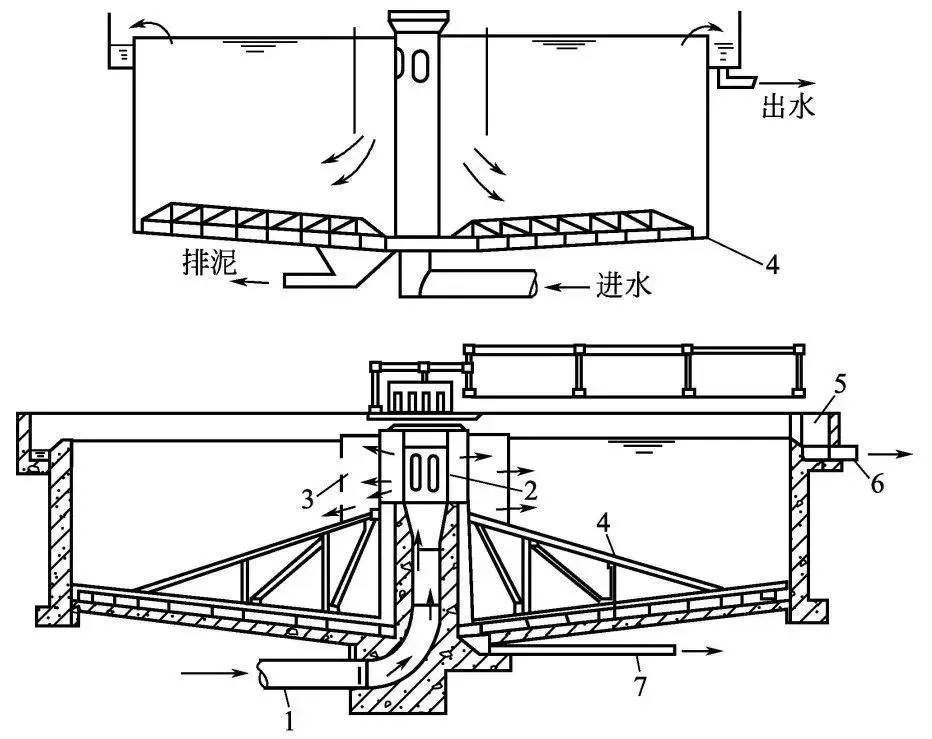

3. Radial Flow Sedimentation Tank

Applicable Conditions:

• Typically used in medium to large-scale treatment plants

• Can serve as a pre-sedimentation tank for high-turbidity water

Advantages:

• Suitable for medium to large-scale plants

• Effective for pre-sedimentation of high-turbidity water

• Strong resistance to shock loads

Disadvantages:

• Higher equipment cost

• More difficult construction for inflow and outflow structures

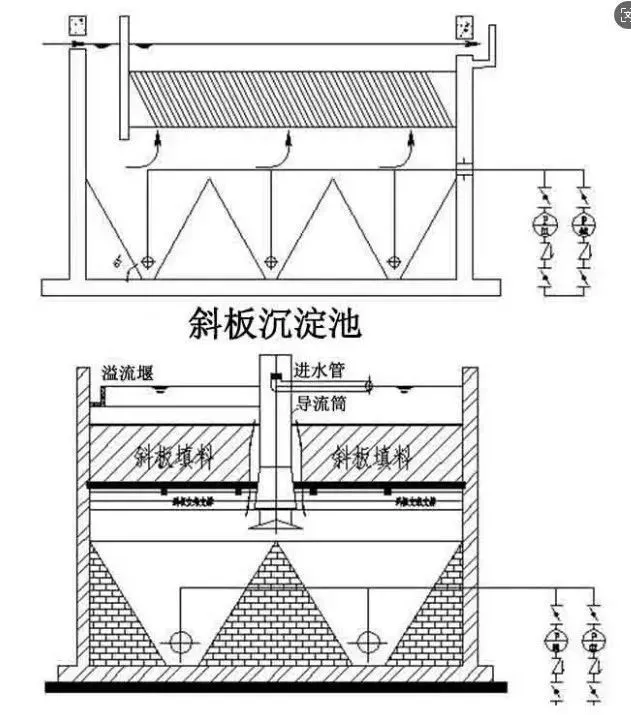

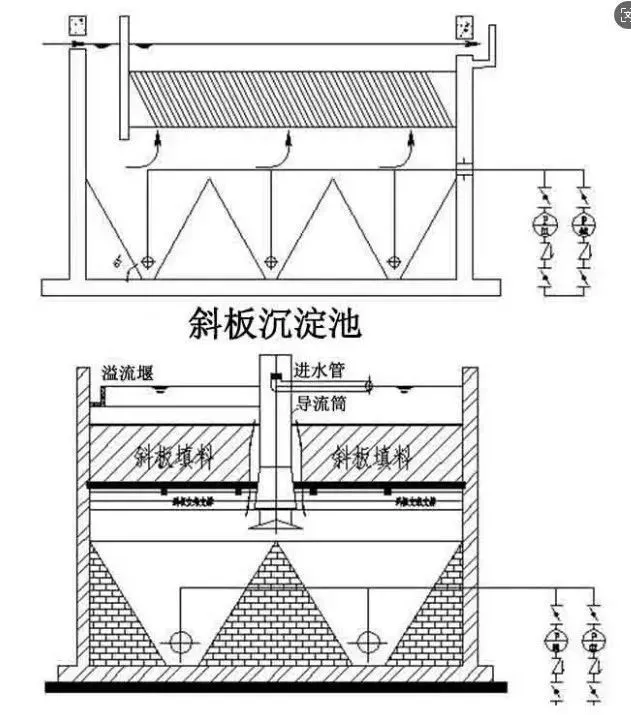

4. Inclined Tube (Plate) Sedimentation Tank

Applicable Conditions:

• Suitable for small to medium-sized water treatment plants

• Ideal for upgrading, retrofitting, and capacity expansion of existing tanks

Advantages:

• High sedimentation efficiency

• Compact tank body with small footprint

Disadvantages:

• Inclined tubes or plates require regular cleaning, leading to high maintenance costs

• If sludge is removed via multiple bottom pipes, control becomes complex

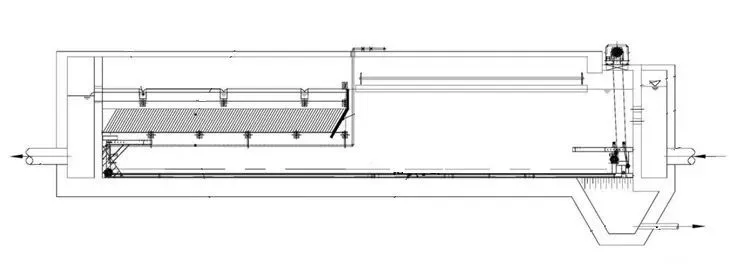

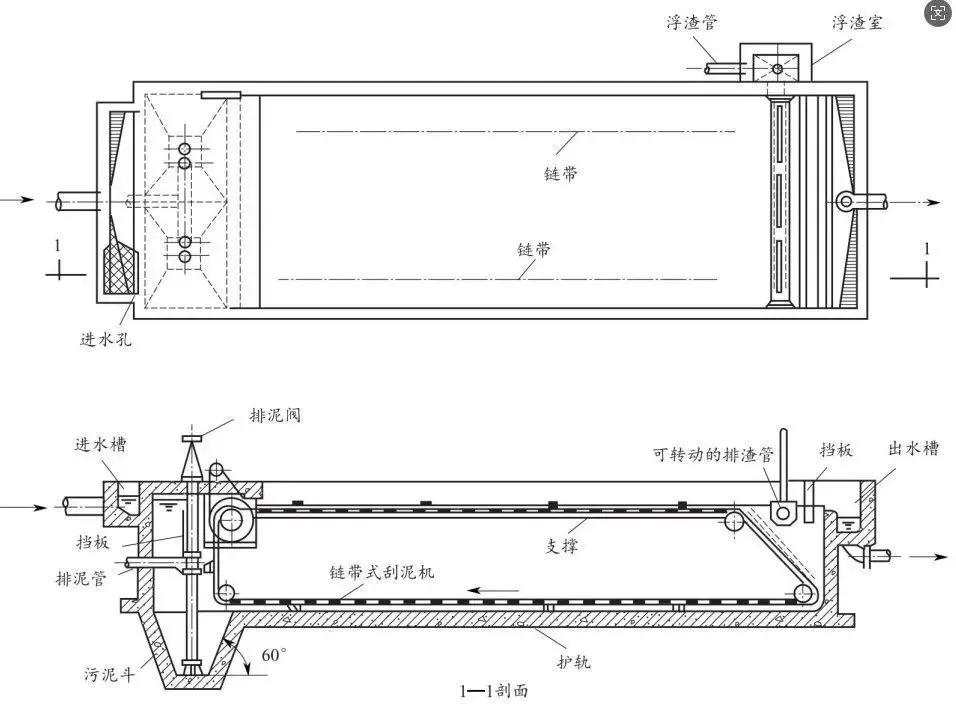

5. Peripheral Inflow and Outflow Rectangular Sedimentation Tank

Applicable Conditions:

• Suitable for medium to large-scale water treatment plants

• Ideal for underground sewage plants, space-limited projects, or retrofitting rectangular biological tanks into sedimentation tanks

Advantages:

• Uniform flow distribution, high tank volume utilization, high sedimentation efficiency, timely sludge removal

• Compact tank design, small footprint, easier construction due to rectangular shape

• Compatible with non-metallic chain-type sludge scrapers that are lightweight, stable, and easy to install

Disadvantages:

• Chain-type sludge scrapers require high construction accuracy

• Inlet distribution troughs need professional hydraulic design

• High equipment specifications; low-end products tend to have high failure rates

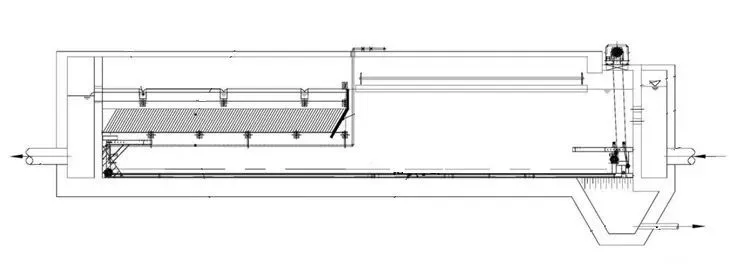

6. Horizontal Flow Combined Sedimentation Tank

Applicable Conditions:

• Suitable for upgrading and expanding wastewater treatment plants

• Ideal for projects with large fluctuations in water volume

Advantages:

• Strong resistance to shock loads; good scalability

• Minimal civil engineering changes for on-site retrofitting

Disadvantages:

• Inclined tubes or plates require regular cleaning, increasing maintenance costs

Sedimentation tanks serve a dual role in wastewater treatment as both a “solid-liquid separation hub” and a “process stabilizer”:

• Primary sedimentation tanks are key for initial pollutant reduction and resource recovery.

• Secondary sedimentation tanks ensure the closed-loop operation and effluent compliance of biological treatment systems.

Together, they enable minimal energy consumption, maximum resource utilization, and stable operation, making them indispensable components of modern wastewater treatment process chains.

Sedimentation tanks (including primary and secondary clarifiers) are the core solid-liquid separation units in wastewater treatment processes. Their performance directly affects water purification efficiency, the stability of subsequent processes, and operational costs. The characteristics of different sedimentation tank types are explained below in terms of “Applicable Conditions,” “Advantages,” and “Disadvantages.”

1. Horizontal Flow Sedimentation Tank

Applicable Conditions:

• Generally used in medium to large-scale water treatment plants

• Can be used as a pre-sedimentation tank when raw water has a high sand content

Advantages:

• Strong adaptability to water treatment and stable performance

• Easy operation and management

• Low construction cost and relatively simple to build

• Effective sludge removal when equipped with mechanical sludge collectors

Disadvantages:

• Requires large land area

• Poor resistance to shock loading

2. Vertical Flow Sedimentation Tank

Applicable Conditions:

• Generally used in small-scale water treatment plants

Advantages:

• Small land footprint

• Compact structure facilitates sludge removal

Disadvantages:

• Difficult to construct

• Low upward flow velocity leads to limited capacity and poor sedimentation efficiency

3. Radial Flow Sedimentation Tank

Applicable Conditions:

• Typically used in medium to large-scale treatment plants

• Can serve as a pre-sedimentation tank for high-turbidity water

Advantages:

• Suitable for medium to large-scale plants

• Effective for pre-sedimentation of high-turbidity water

• Strong resistance to shock loads

Disadvantages:

• Higher equipment cost

• More difficult construction for inflow and outflow structures

4. Inclined Tube (Plate) Sedimentation Tank

Applicable Conditions:

• Suitable for small to medium-sized water treatment plants

• Ideal for upgrading, retrofitting, and capacity expansion of existing tanks

Advantages:

• High sedimentation efficiency

• Compact tank body with small footprint

Disadvantages:

• Inclined tubes or plates require regular cleaning, leading to high maintenance costs

• If sludge is removed via multiple bottom pipes, control becomes complex

5. Peripheral Inflow and Outflow Rectangular Sedimentation Tank

Applicable Conditions:

• Suitable for medium to large-scale water treatment plants

• Ideal for underground sewage plants, space-limited projects, or retrofitting rectangular biological tanks into sedimentation tanks

Advantages:

• Uniform flow distribution, high tank volume utilization, high sedimentation efficiency, timely sludge removal

• Compact tank design, small footprint, easier construction due to rectangular shape

• Compatible with non-metallic chain-type sludge scrapers that are lightweight, stable, and easy to install

Disadvantages:

• Chain-type sludge scrapers require high construction accuracy

• Inlet distribution troughs need professional hydraulic design

• High equipment specifications; low-end products tend to have high failure rates

6. Horizontal Flow Combined Sedimentation Tank

Applicable Conditions:

• Suitable for upgrading and expanding wastewater treatment plants

• Ideal for projects with large fluctuations in water volume

Advantages:

• Strong resistance to shock loads; good scalability

• Minimal civil engineering changes for on-site retrofitting

Disadvantages:

• Inclined tubes or plates require regular cleaning, increasing maintenance costs

Sedimentation tanks serve a dual role in wastewater treatment as both a “solid-liquid separation hub” and a “process stabilizer”:

• Primary sedimentation tanks are key for initial pollutant reduction and resource recovery.

• Secondary sedimentation tanks ensure the closed-loop operation and effluent compliance of biological treatment systems.

Together, they enable minimal energy consumption, maximum resource utilization, and stable operation, making them indispensable components of modern wastewater treatment process chains.

Next: no data!