Rotary Drum Screen

The rotary drum fine screen is a highly efficient fine solid-liquid separation unit, integrating screening, cleaning, conveying, and dewatering in one compact structure.

The rotary drum fine screen is a highly efficient fine solid-liquid separation unit, integrating screening, cleaning, conveying, and dewatering in one compact structure.

Application Scope

• Municipal wastewater treatment plants

• Rainwater and stormwater runoff pretreatment

• River intake and pump station protection

• Upgrading of old treatment facilities

Application Scope

• Municipal wastewater treatment plants

• Rainwater and stormwater runoff pretreatment

• River intake and pump station protection

• Upgrading of old treatment facilities

Product Overview

Key Characteristics

- ㅤAdvantages

- ㅤStructure & Materials

- ㅤCore Components

Advantage

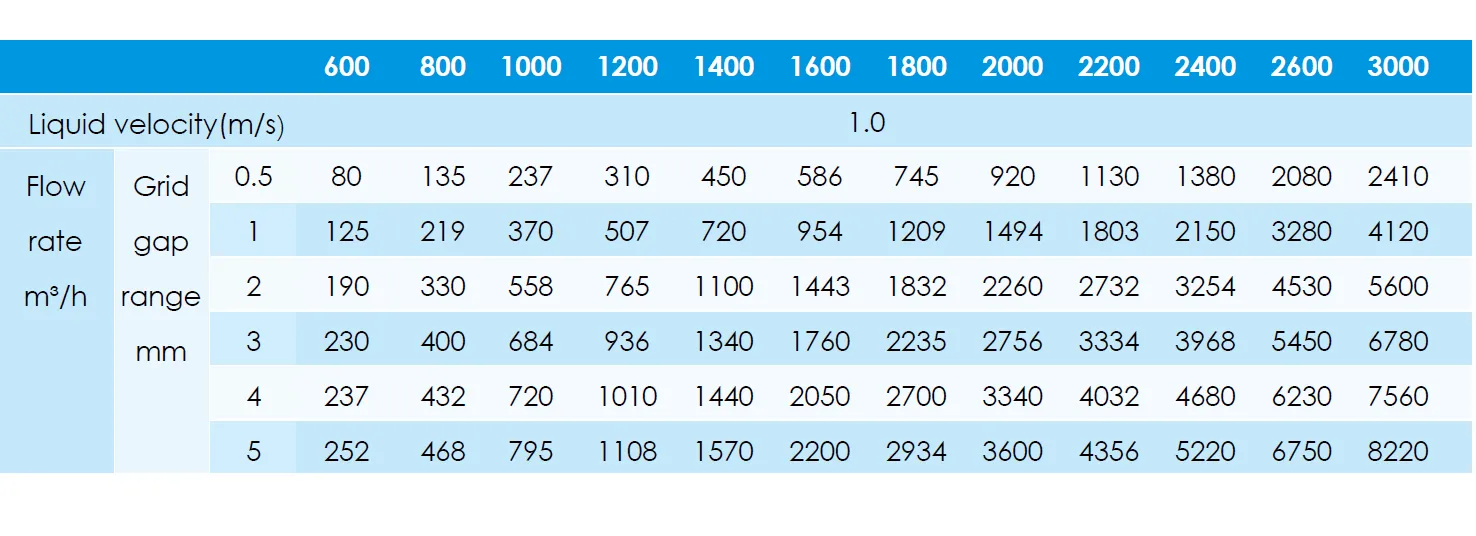

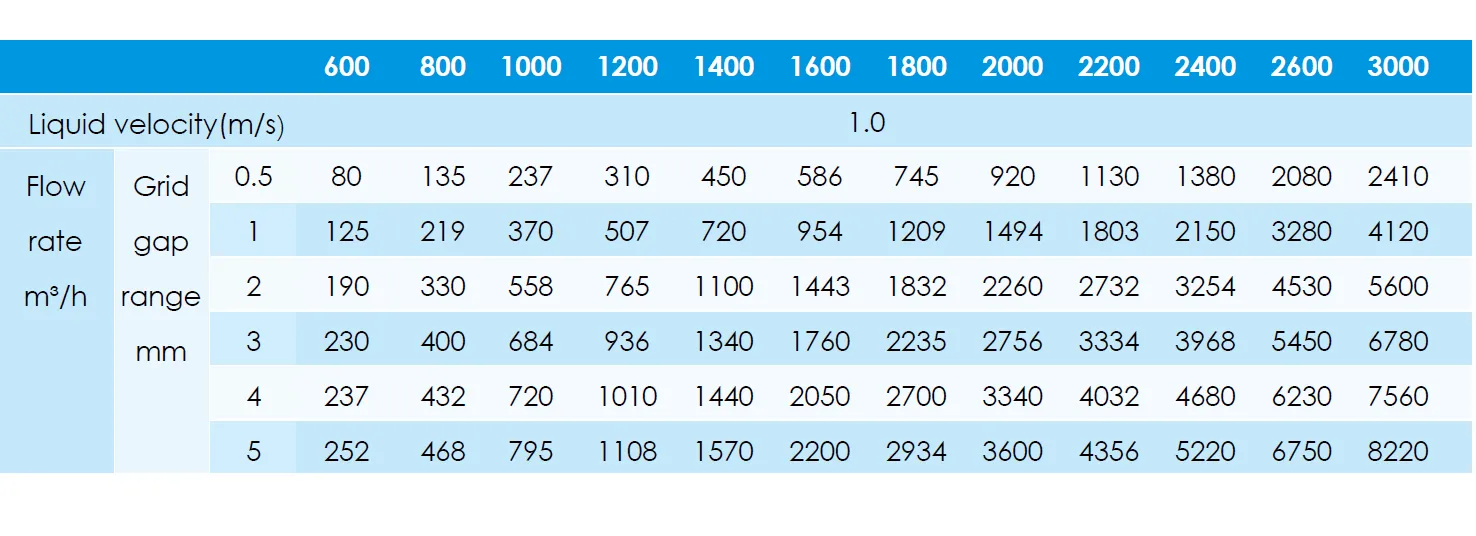

• The range of screen bar gaps is wide, from 0.5 to 12mm.

• Forming a 35° angle with the water flow, the resulting baffling flow can greatly improve the separation of fine dirt.

• The self - contained flushing device automatically cleans during operation, reducing blockages and having a low maintenance cost.

• Compared with traditional screens, it has a large water - passing flow rate, less head loss, and a smaller accumulation plane in front of the screen.

• High dirt - interception efficiency, closed - type conveying, causing no environmental pollution.

• The equipment can be fully automatically controlled, with smooth operation, low energy consumption, and low noise.

• Integrated design of retrieving, conveying, and pressing treatment, with a compact structure and small footprint.

Advantage

• The range of screen bar gaps is wide, from 0.5 to 12mm.

• Forming a 35° angle with the water flow, the resulting baffling flow can greatly improve the separation of fine dirt.

• The self - contained flushing device automatically cleans during operation, reducing blockages and having a low maintenance cost.

• Compared with traditional screens, it has a large water - passing flow rate, less head loss, and a smaller accumulation plane in front of the screen.

• High dirt - interception efficiency, closed - type conveying, causing no environmental pollution.

• The equipment can be fully automatically controlled, with smooth operation, low energy consumption, and low noise.

• Integrated design of retrieving, conveying, and pressing treatment, with a compact structure and small footprint.

Send Your Message To Us