Automatic Filter Press for Compact Sludge Dewatering

A key equipment for efficient municipal and industrial sludge dewatering. Motor-driven, it saves 30% floor space and 60% energy, finishing each batch in 30-60 min with 45%-60% moisture. Runs 24/7 unattended, auto-cleans filter cloth.

A key equipment for efficient municipal and industrial sludge dewatering. Motor-driven, it saves 30% floor space and 60% energy, finishing each batch in 30-60 min with 45%-60% moisture. Runs 24/7 unattended, auto-cleans filter cloth.

Application

• Suitable for sludge dewatering in urban waterworks and sewage plants.

• Especially ideal for scenarios requiring improved dewatering capacity in existing buildings with demands for miniaturization and lightweight design.

Application

• Suitable for sludge dewatering in urban waterworks and sewage plants.

• Especially ideal for scenarios requiring improved dewatering capacity in existing buildings with demands for miniaturization and lightweight design.

Product Overview

| Model | DCS15N | DCS21N |

| Filter Area(m²) | 50/100/150/200/250/300 | 300/350/450/550/600 |

| No.of Filter Chambers | 14/26/40/52/66/76 | 42/48/62/76/82 |

| Filter Plate Size(m) | 1.5*1.5 | 2.1*2.1 |

| Filter Chamber Volume (L) | 742/1378/2120/2756/3074/3498 | 4326/4944/6386/7828/8446 |

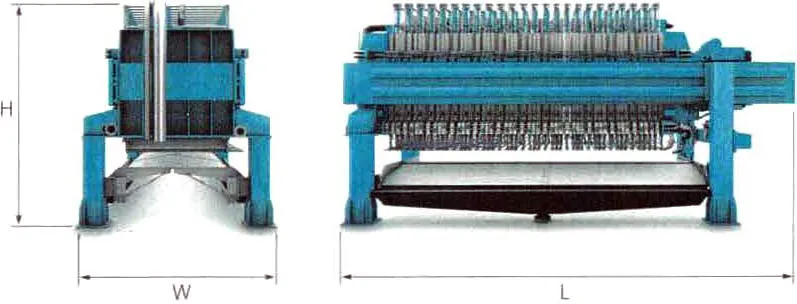

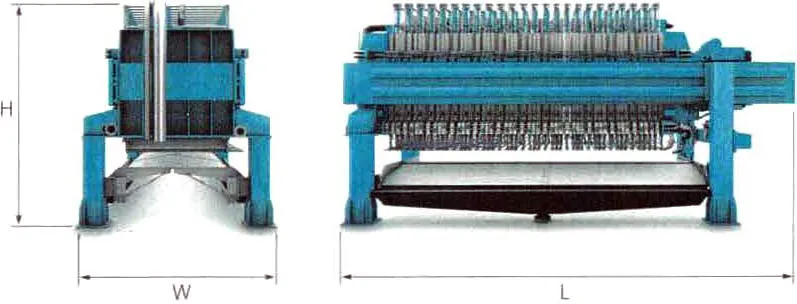

| Dimensions(m)L | 6/7.4/9.1/10.6/12.3/13.5 | 10.8/11.3/12.6/13.8/14.4 |

| W | 2.9 | 3.9 |

| H | 3.9 | 4.8 |

| Treatment Capacity (t/d)Dry Solid Sludge | 3.6-21.6 | 21.6-50.4 |

| Moisture Content 60% | 19-54 | 54-126 |

| Moisture Content 80% | 18-108 | 108-252 |

| Model | DCS15N | DCS21N |

| Filter Area(m²) | 50/100/150/200/250/300 | 300/350/450/550/600 |

| No.of Filter Chambers | 14/26/40/52/66/76 | 42/48/62/76/82 |

| Filter Plate Size(m) | 1.5*1.5 | 2.1*2.1 |

| Filter Chamber Volume (L) | 742/1378/2120/2756/3074/3498 | 4326/4944/6386/7828/8446 |

| Dimensions(m)L | 6/7.4/9.1/10.6/12.3/13.5 | 10.8/11.3/12.6/13.8/14.4 |

| W | 2.9 | 3.9 |

| H | 3.9 | 4.8 |

| Treatment Capacity (t/d)Dry Solid Sludge | 3.6-21.6 | 21.6-50.4 |

| Moisture Content 60% | 19-54 | 54-126 |

| Moisture Content 80% | 18-108 | 108-252 |

Key Characteristics

- ㅤAdvantages

- ㅤStructure & Materials

- ㅤCore Components

Core Features

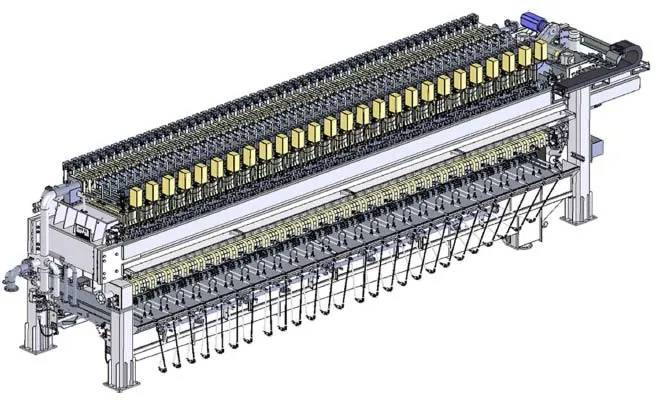

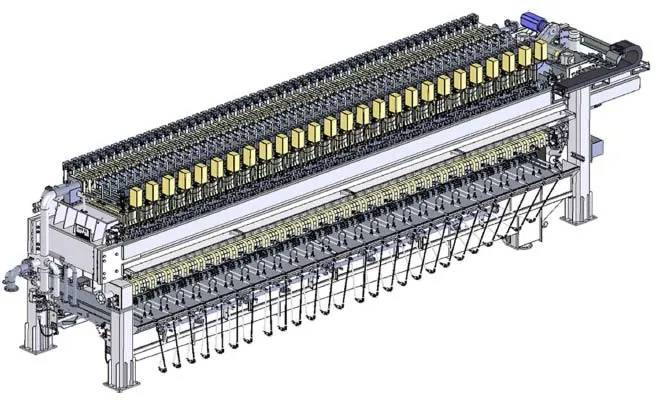

· High Automation: Enables 24-hour unattended automatic operation, fully automated from clamping to filtration and cleaning, reducing labor costs.

· Remarkable Dewatering Efficiency: Single batch operation in 30-60 minutes. High-pressure diaphragm pressing thins sludge cakes to 1cm, with moisture content as low as 45%-60% (45%-55% with special conditioning agent).

· Technical & Drive Upgrade: Motor drive replaces traditional hydraulic drive, eliminating hydraulic push rods, reducing floor space, and lowering energy consumption (approx. 10kW· h per batch).

· Optimized Structural Design:

Filter cloth traveling design ensures reliable sludge discharge without sticking.

Two-stage sludge discharge shortens filter plate opening space, reducing machine length.

Independent filter cloth drive motor and high-pressure cleaning device extend filter cloth life (up to 1 year under full load).

· Cost & Service Advantages:

Specialized sludge conditioning agent dosage as low as 0.2%, eliminating the need for PAM, iron salts, etc., reducing chemical costs.

Equipped with remote monitoring module for full-life-cycle online service and real-time fault response.

Core Features

· High Automation: Enables 24-hour unattended automatic operation, fully automated from clamping to filtration and cleaning, reducing labor costs.

· Remarkable Dewatering Efficiency: Single batch operation in 30-60 minutes. High-pressure diaphragm pressing thins sludge cakes to 1cm, with moisture content as low as 45%-60% (45%-55% with special conditioning agent).

· Technical & Drive Upgrade: Motor drive replaces traditional hydraulic drive, eliminating hydraulic push rods, reducing floor space, and lowering energy consumption (approx. 10kW· h per batch).

· Optimized Structural Design:

Filter cloth traveling design ensures reliable sludge discharge without sticking.

Two-stage sludge discharge shortens filter plate opening space, reducing machine length.

Independent filter cloth drive motor and high-pressure cleaning device extend filter cloth life (up to 1 year under full load).

· Cost & Service Advantages:

Specialized sludge conditioning agent dosage as low as 0.2%, eliminating the need for PAM, iron salts, etc., reducing chemical costs.

Equipped with remote monitoring module for full-life-cycle online service and real-time fault response.

Prev: Screw sludge dewatering

Next: no data!

Send Your Message To Us